For the aluminum alloy automotive parts manufacturers for product quality, accuracy and durability of the mold is very obvious.

Ferrous metal casting, mold more in order to form a mold cavity, the the general mold itself does not directly contact with the liquid metal, especially for non-metallic mold castings of complex shape, especially contact with hot liquid metal shapes materials, mainly sand, modeling materials become the main factors affecting the quality of the casting. Gravity casting, casting performance in mass production, the shape of the casting is generally directly by the mold formed due to the low melting point of aluminum alloy, such as engine aluminum alloy cylinder block, cylinder head, which is not only help to improve labor productivity, but more importantly, by adjusting the temperature of the mold in different parts of the distribution, to control the casting of the organizational structure and grain size, improve casting quality, at the same time, avoid the extensive use of modeling materials brought by environmental pollution, improve labor conditions in the workshop.

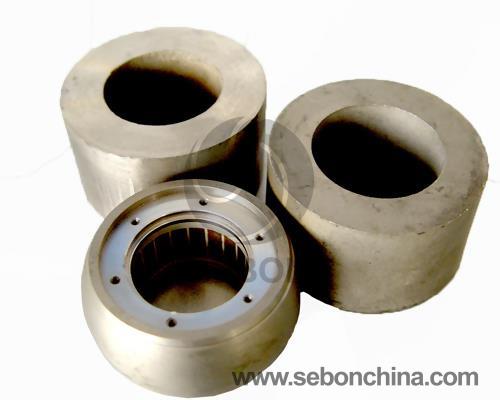

With varying degrees of castings of complex shape, aluminum gravity casting mold is not the same. Even if it is the same part, different casting process, mold forms often have different Nevertheless, aluminum gravity casting mold or have something in common.

First, the mold have a good volume heat capacity. Thick mold and modules meet the requirements, not only is the die life assurance, and have a very important role in the regulation of the temperature field in the mold continuous work process. Some mold factory, in order to reduce costs, conserve materials, simply to reduce the effective thickness of the mold in order to achieve the purpose of weight reduction, does not know that this is not only greatly reduce the life of the mold and the casting easily deformed, affect the dimensional accuracy of castings, severe will lead to casting bulk scrap, to foundries losses, more serious damage to the reputation of mold factory.

Secondly, we must choose the casting process, the casting process is directly related to the level of the casting quality and process yield. Some mold manufacturer, has started using solidification simulation to the casting process aided design, computer simulation of filling and solidification process, the hot junction site and easy to produce casting defects to be overcome, which is designed to improve the casting process and reliable effectively prevent mold unnecessary rework during debugging, it is very important and effective.