Magnesium Alloys Forming Technique in Auto Parts

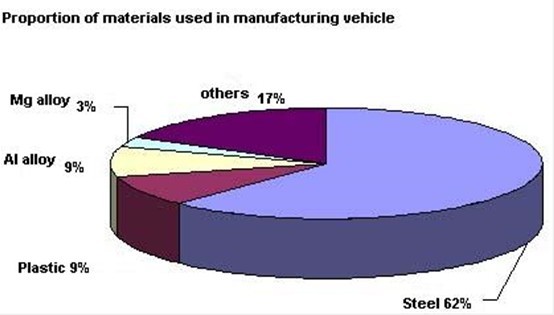

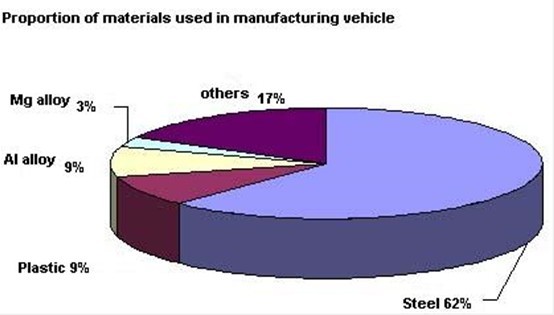

Magnesium alloy has a higher strength than steel and a better performance than aluminum alloy and the engineering plastics. Magnesium alloy also has high temperature resistance, corrosion resistance and peristalsis resistance. Magnesium is the lightest metals that are currently used in the auto industry, it is 1/3 lighter than aluminum,3/4 lighter than steel, 1/5 lighter than nonmetal plastic.Therefore, Magnesium alloys are the ideal materials that are suitable for light car, Magnesium alloy die-casting pieces can replace some complex structural components, for example, steel parts manufactured by stamping and welding technology of dashboards skeleton weight 10 kg each, if the parts are replaced by

Magnesium alloy die casting, its weight is just 4 kg, greatly reduced the producing cost.

With continuous development of new Magnesium alloy materials and completion of processing technology, the application of Magnesium alloy in car market will develop continuously and growing steadily.Die-casting forming technology of Magnesium alloy production has been the focus of automobile industry, demand for Magnesium alloy die casting accounts for 80% of the demand for Magnesium alloys in auto industry. Besides satisfying the high temperature resistance and peristalsis resistance, Magnesium alloy materials used in automobile should also take the design, processing, surface treatment and related whole-coasting process into consideration.Since Magnesium alloy casting has the prominent advantage of cast ability, Casting wall thickness can reach 1 ~ 1.5 mm, and degree of mold slope can be 1 ° - 2 °. Although the Magnesium alloy casting still stress on die-casting, it still faces the performance and cost problems. Therefore, a new type of technology -- the semi-solid Magnesium alloy processing technologies have emerged. This technology is mainly used for the production of Magnesium and aluminum alloy casting.

The application of Magnesium alloy in the car is prospect, Output growth rate of Magnesium die casting in European and American countries is 25% per year. The shell of Audi A6 car transmission which is casted by Magnesium alloy is only 14.2kg,Magnesium alloy casting is primly used as dashboard skeleton by the Audi. Ford auto company replaced the steel skeleton with Magnesium alloy production for seat skeleton,making seat weight reduced from 4 kg to 1 kg. Ford is studying the method to produce gas cylinder body with Magnesium alloy. Mitsubishi Japan and Australia ministry of science and technology have cooperated and developed a super light Magnesium alloy engine which weights 7.5 kg only .Six Magnesium alloy cylinders have been put into batch production in-line by BMW. The American GM has produced Magnesium die casting intake tube. Renault company has produced Magnesium alloy wheel casting. In recent years, domestic will also successively established some large foreign Magnesium die-cast enterprises, Henan SEBON auto parts will go further among all these conditions.